|

Project First Group Chester

| Customer |

First Group |

|

| City |

Chester / UK |

| Supplier |

Kärcher |

|

|

|

|

|

|

|

Planning |

Commissioning |

Hand over |

|

9/2003 |

10/2003 |

10/2003 |

|

|

|

|

|

|

Projectdescription:

The plant is used to wash trains with body and

underframewash of trains .

The wash will executed with alcaline detergent.

The washtime is appr. 20 min for one train with front and

rearwash. No operator is necessary. The traindriver starts the washprogramm

The project First Group Chester includes

| Development of controllersoftware bodywashplant |

| Development of controllersoftware

underframewashplant |

| PC-based data recording |

| Commissioning in Chester / UK |

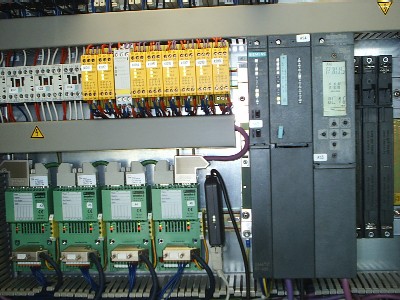

Controlling:

To control the plant a Simatic S7 400

is used with a CPU 414-3 DP . The Sensor/Actors are controlled viaInterbus - S

A remote touch panel is used to communicate via

fiber-optic and PROFIBUS-DP protocol to the CPU.

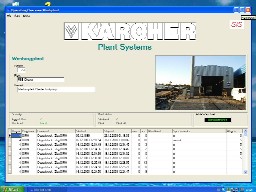

PC based data recorder:

Each washprocedure will recorded with

| Date |

| Time |

| Washprogram |

| Washtime |

Bodywash:

The Bodywash is done with Front- rear- and sidewash. The

train get the sidewash by moving train.

A dryer at the plant exit dries the train

A speed-measurement signals the train driver that he is

to fast or to slow.

Underframewash:

The Underframewash is used to clean the trains underframe

before maintenance work . The train will positioned over 2 trolleys, which

move from one end to the other and wash the train with high-pressure

Critical sections like Transformers, Inverters will

automatically not washed.

|