|

Project Kärcher KCRC-West Hongkong

| Customer |

KCRC Hongkong |

|

| City |

Hongkong / China |

| Supplier |

Kärcher |

|

|

|

|

|

|

|

Planning |

Commissioning |

Hand over |

|

4/2003 |

6/2003 |

8/2003 |

|

|

|

|

|

|

Projectdesription:

The plant is used to wash metro-trains from the Hongkong

Metro. The washplant can wash the train with acid and alcaline detergent.

The washingtime is between. 11-15 min for a 6-cartain

(120m) with front and rearwash . It is no operating personal at the plant

necessary.

The project KCRC West Hongkong contains

| development from plant software |

| communication via fiber optic to control center |

| commissioning |

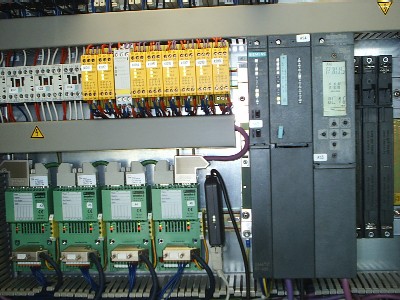

Controlling:

To control the plant a Simatic S7 400

is used with a CPU 414-3 DP . The Sensor/Actors are controlled viaInterbus - S

A remote touch panel is used to communicate via

fiber-optic and PROFIBUS-DP protocol to the CPU.

Control Room:

The Operating of the plant is done by the operaters in

the DCC-Controlroom.The distance to the plant is appr. 1,2km. The incomming

train must report to the Operator . If the Operator starts the pla, the

Traindriver is authorized to drive throw the plant.

Bodywash:

The Bodywash includes Front-Rearwash. It will be exectued

after the train stand in correct postion. The side-wash is done by moving

train. The train driver get order via visual matrixboards in english/chinese

language.

A measurement of the train speed shows the train driver

the actual speed and the information that he move to fast, or to slow.

Underframewash:

The Underframewash is used to clean the trains underframe

before maintenance work . The train will positioned over 2 trolleys, which

move from one end to the other and wash the train with high-pressure

Critical sections like Transformers, Inverters will

automatically not washed.

|